Whether you’re designing a new sustainable home or tackling a hands-on natural building project, the foundation beneath your earthen floor is key. The type of subfloor you choose will determine not only the durability of the finished surface but also how well it supports comfort, efficiency, and long-term resilience.

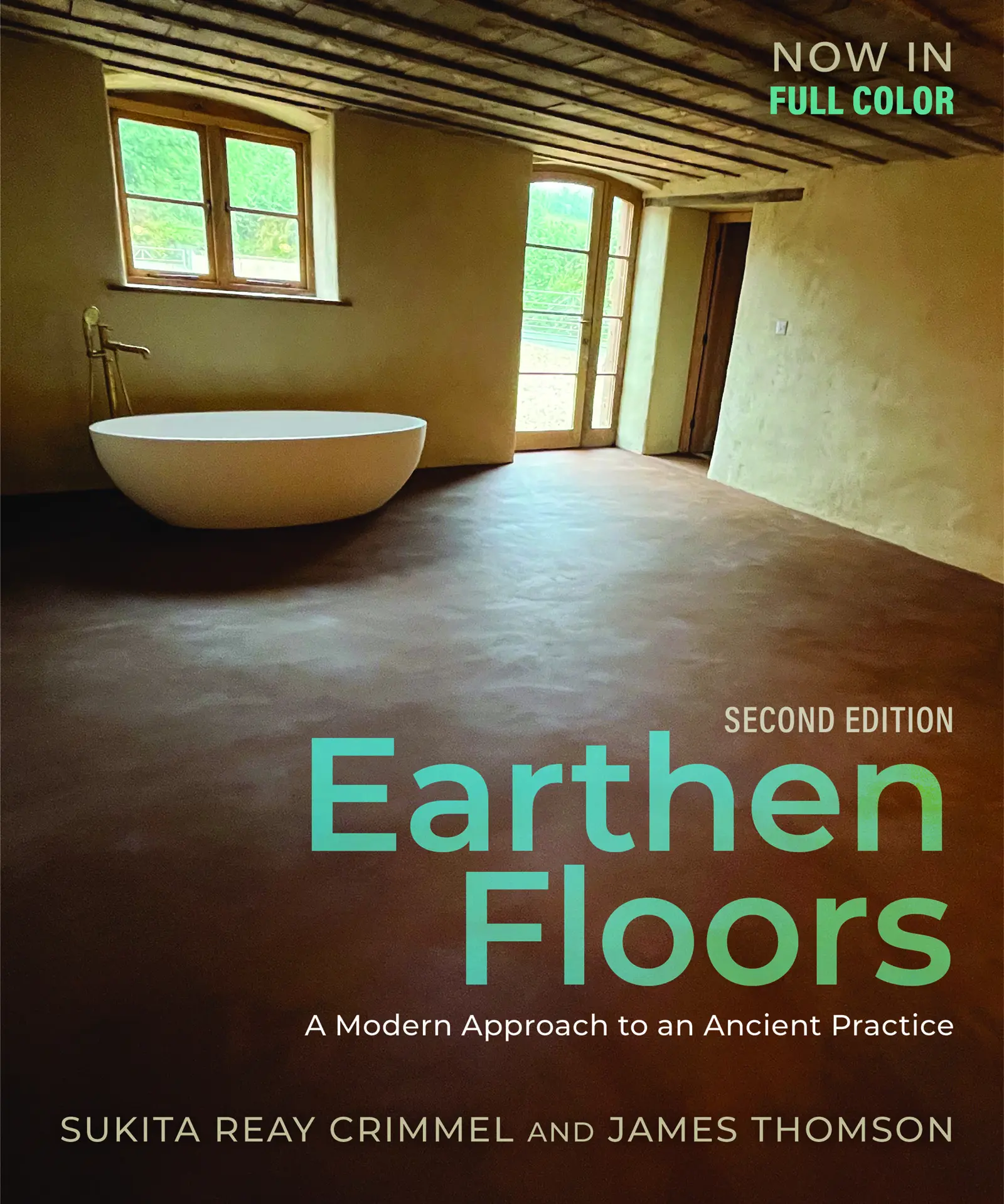

The following excerpt from the newly released Earthen Floors, Second Edition, by Sukita Reay Crimmel and James Thomson, highlights the most common subfloor options—and what makes them suitable for earthen floors.

Types of Subfloors and their Suitability for Earthen Floors

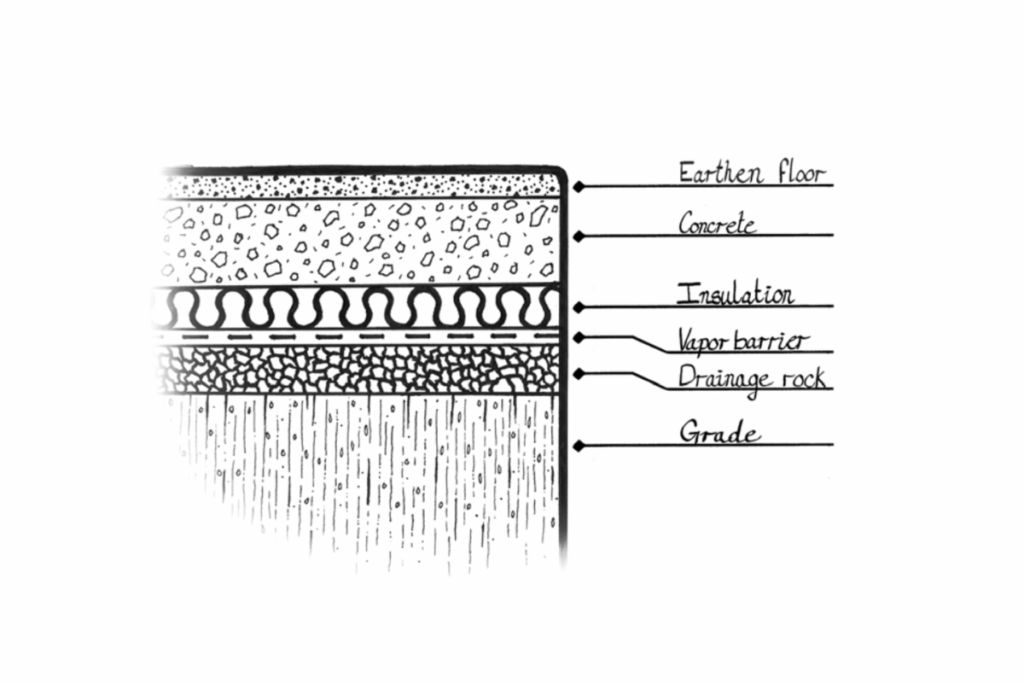

Concrete slab

Concrete slabs are common floor systems for conventional homes. They are typically strong enough to support the weight of an earthen floor of almost any thickness. If the slab is free of cracks, the earthen floor can be poured directly on it with little preparation, though a vapor barrier may be needed (see below). Sometimes an old concrete slab is in very poor structural shape, with lots of cracks or loose sections. There may be control joints larger than ¼”.

There are a few techniques to employ to make sure these cracks do not transfer up to the finished floor:

- Pour an earthen base coat on top of the slab (see “Earthen base coats” in this chapter) with plenty of chopped straw to create a solid base for the finish coat. If the slab is in especially bad shape, it is best to lay down a thin, flexible membrane to separate the earthen layer from the cracked concrete. Examples include house wrap, a plastic vapor barrier, or a vapor retarder such as Aqua Bar B or Red Rosin paper. Make sure to have enough material on top of the membrane to weigh it down and eliminate weak spots, at least 1½”. The finish coat can be installed on top of the base.

- Imbed a reinforcing “grid” into the floor. Examples include fiberglass stucco mesh and loose-weave landscape cloth, often made of burlap, jute, or hemp. See chapter 12 for more about using mesh. The finish coat may need to be a little thicker than usual (1″–1½” ), depending on the condition of the subfloor.

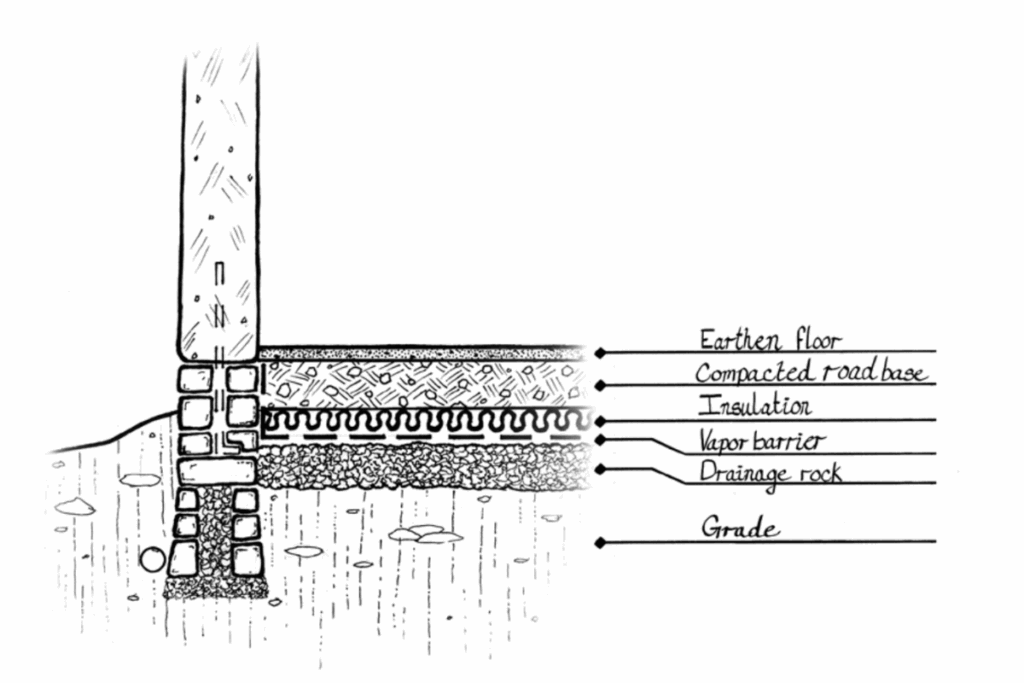

Compacted gravel (roadbase)

A compacted gravel subfloor is a good option for on-grade floors in new construction. This technique creates a solid, well-drained subfloor that minimizes the use of concrete. It is little used in conventional construction but is popular in the natural building field because it requires no cement, a high-embodied energy product. Because the surface of a compacted gravel subfloor may not be perfectly flat and may include some loose gravel, a final earthen layer of at least ¾” above the highest point in the field (floor area) is recommended. See appendix D for guidance.

Earthen base coat

A thick layer of earthen floor mix can also be used as a subfloor; often this is called a base coat. A base coat will be made of coarser material than is used for the top coat. This base coat may sit on top of an existing slab (concrete or compacted gravel), or be the main supporting layer in an on-grade sub-floor system. It’s even possible to use multiple base coats. See appendix E for more on how to use an earthen base coat.

There are some specific situations where an earthen base coat should be used:

- To raise the floor level for design reasons. If the thresholds or transitions to adjacent flooring types would be easier to deal with if the finished floor level was a couple of inches higher, use a base coat to add the additional thickness.

- When using radiant heat. If the heating system design calls for more than 1½” of material above the tubes or electric elements, pour a base coat to cover the tubes. See appendix F for more information.

- To bring more thermal mass into the room. See chapter 2 for a discussion of thermal mass. This is not commonly needed, as a 1″ earthen floor provides a lot of thermal mass.

- To level out a nonlevel subfloor. If the subfloor is not level, it may be easier to make the correction with a base coat and then pour a finish layer on top.

- To provide additional stabilization. If working on a loose subfloor (e.g., an old concrete pad that has broken and cracked in places) or add- ing rigid foam insulation on top of a slab or compacted grade, a base coat will add additional strength and stability. A minimum of 4″ is needed to provide adequate stabilization over rigid insulation sheets. Note: This only applies when working on an on-grade subfloor. An unstable wood-framed subfloor will not benefit from the addition of the extra weight of a base coat; instead, additional structural support is needed.

- As an alternative subfloor option to compacted gravel. In some cases, an on-grade compacted gravel subfloor may not be a suitable or desired option. There could be a few reasons for this. One, perhaps the appropriate materials or tools are not available (roadbase cannot be readily acquired, a plate compactor is not available, etc.). Two, if the space is already enclosed and ventilation is poor, operating a plate compactor is not recommended as the exhaust fumes will quickly become unbearable and even dangerous to the operator. Three, a compacted gravel subfloor may not result in as flat a surface as some installers prefer. An earthen base coat can be poured and troweled and will leave a very flat surface for the final coat, while a compacted gravel subfloor has more irregularity. To build an earthen subfloor, start by following the instructions in appendix D and replace the compacted gravel layer with a poured base coat, as described in appendix E. See the compacted gravel subfloor diagram above, and replace the compacted roadbase layer with an earthen base coat.

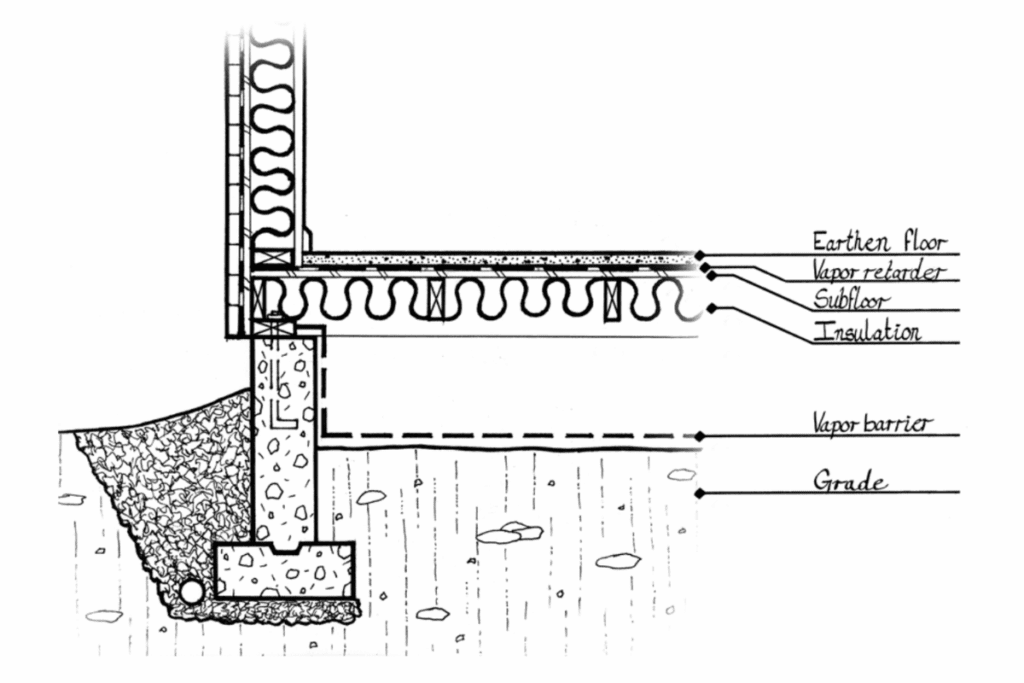

Wood-framed subfloor

A wood-framed subfloor, built with wood beams, joists, and planks or plywood, is the standard type of floor in many conventionally built houses. The main considerations for installing an earthen floor over a wooden subfloor are whether the subfloor can support the weight without too much deflection, and protecting the wood against the moisture in the earthen mix until it has a chance to dry.

Weight considerations: It’s unlikely that the weight of an earthen floor would actually damage a wood-framed subfloor, but it is certainly possible that there will be too much bounce and movement in the wood, causing an earthen floor to crack over time. Most wood-framed subfloors (including second stories) that are built to recent code specifications should be able to accommodate 20 lbs. per square foot of weight. Recall from chapter 2 that an earthen floor is about 10 lbs. per square foot at 1″ thick. The recommended thickness is ¾”–1″, and thus should be well within the capacity of most framing. To be certain, consult with a structural engineer. If this is not an option, it is possible to perform a rudimentary test to determine the amount of movement, called “deflection,” in a wood floor.

It is a good idea to protect the wood subfloor from becoming saturated with water from the wet earthen mix while installing the earthen layer. Before the pour, affix a vapor retarder to the subfloor with a hammer tacker and staples or tape. A vapor retarder is a membrane that helps to protect the wooden subfloor from getting wet during installation (which could cause it to warp). Thin tar-impregnated paper or red rosin paper are examples of vapor retarders (see appendix C for product listings). Allow a 3-inch overlap. Staple and tape the seams to prevent the vapor retarder from shifting, and take care not to rip the paper during installation.